College of Engineering

10 Production of High-Purity Calcite and Rare Earth Elements from Phosphogypsum

Rachel D’Agostini (University of Utah)

Faculty Mentor: Xuming Wang (Materials Science and Engineering, University of Utah)

Phosphogypsum (PG) is a solid waste from phosphoric acid production, and is primarily composed of CaSO4.2H2O. It is estimated that about 200 Mt/a of PG is generated globally in the phosphate industry (Parreira et al. 2003). Due to impurities (such as phosphate, fluorides, sulfates, trace metals and radioactive elements) only 15% of the PG is recycled as building material and soil stabilization amendments (Tayibi et al. 2009). Most of the PG is stored in large stacks across the world. The large number of PG stacks is not only occupying land space, but is also an environmental problem (Rutherford et al. 1994, 1996). On the other hand, the PG could be a material resource. For example, research indicates that the content of REE (Rare Earth Elements) in PG is about 112-300 ppm (Zhang 2014) which is a significant REE resource.

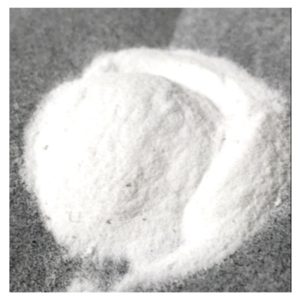

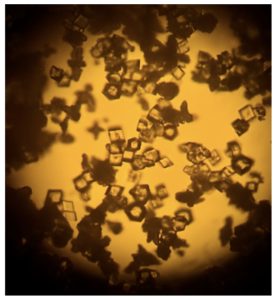

Current study for recovery of REE from PG using NH4Cl dissolution is in progress. In addition, preparation of high purity of CaCO3 through CO2 mineralization is included in our research (Figure 1). The processing parameters including dissolution time, temperature, and liquid/solid ratios are being explored to determine the optimum conditions. Fourier-transform infrared spectroscopy (FTIR) is being used to examine the products, and a Ca++ ion selective electrode is being used to observe dissolution and carbonate formation processes. The preliminary results show the feasibility of using the PG dissolution – CO2 mineralization process to recover REE and produce CaCO3 from PG. The advantage of this processing is to use the solid waste PG and greenhouse gas CO2 as feed materials to produce valuable products, REE and CaCO3. Future research will include extraction of REE from solution.

Figure 1. CaCO3 product from phosphogypsum by using PG dissolution – CO2 mineralization processing.

Bibliography

Parreira, A.B., Kobayashi Jr., A.R.K., Silvestre, O.B., 2003. Influence of Portland cement type on unconfined compressive strength and linear expansion of cement-stabilized phosphogypsum. Journal of Environmental Engineering 129, 956-960.

Rutherford, P.M., Dudas, M.J., Samek, R.A., 1994. Environmental impacts of phosphogypsum. The Science of the Total Environment 149(1-2), 1-38.

Rutherford, P.M., Dudas, M.J., Arocena, J.M., 1996. Heterogeneous distribution of radionuclides, barium and strontium in phosphogypsum by-product. Science of the Total Environment 180(3), 201-209.

Tayibi, H., Choura, M., Lopez, F.A., et al, 2009. Environmental impact and management of phosphogypsum. Journal of Environmental Management, 90(8), pp. 2377-2386.

Zhang, P ., 2014. Comprehensive recovery and sustainable development of phosphate resources. Procedia Engineering 83, 37 – 51.