John and Marcia Price College of Engineering

8 Comparing the Performances of Multilevel Diffractive Lenses and Fresnel Zone Plates of High Numerical Aperture.

Jack Doughty; Rajesh Menon; and Apratim Majurnder

Faculty Mentor: Rajesh Menon (Electrical and Computer Engineering, University of Utah)

Abstract

This study investigates the performance of Multilevel Diffractive Lenses (MDLs) in comparison to Fresnel Zone Plates (FZPs) under identical geometric and fabrication constraints, focusing on high numerical apertures (NAs) of 0.7, 0.9, and 0.99. By employing the direct binary search inverse design algorithm, MDLs were optimized starting from the FZP design. Simulations were conducted at a wavelength of 0.532 μm using MEEP and RSoft to validate the designs. The results indicate that MDLsexhibit superior efficiency, intensity, and reduced aberrations compared to FZPs. At an NA of 0.99, the MDL demonstrated a Figure of Merit (FoM) of 16.0350, a 59.52% improvement over the FZP’s FoM of 10.0516. Both lenses showed identical Full-Width at Half Maximum (FWHM) values of 0.29287 μm, indicating similar resolving power. However, the MDL’s depth of field (DOF) was 17.65% shorter than that of the FZP, implying a tighter focus capability. Despite the minimal difference in DOF, the MDL’s higher efficiency and intensity distribution make it a promising alternative to FZPs in advanced optical applications. This study supports the potential of MDLs to enhance imaging systems, miniaturized optical devices, laser beam shaping, and fiber optics, paving the way for future innovations in thee fields.

Background

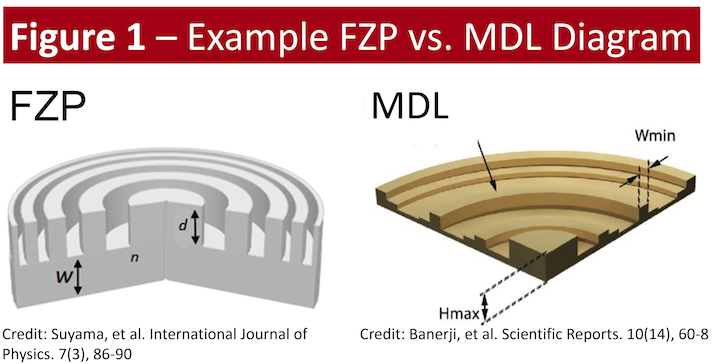

Diffractive optical elements (DOEs) have revolutionized the field of optics by offering compact, lightweight, and highly efficient solutions for precise light manipulation [1]. These characteristics make DOEs particularly suitable for applications where weight and space constraints are critical, such as microscopy, beam shaping, and fiber optics. Among the various types of DOEs, the Fresnel Zone Plate (FZP) has been one of the most popular and widely utilized lenses. The FZP consists of concentric rings that alternate between transparent and opaque regions, focusing light through the principle of diffraction. It’s simple yet effective design has made it a staple in numerous optical applications [2].

Advancements in micro-fabrication techniques, including imprint lithography and electron-beam lithography, have enabled the creation of even more compact, complex, and precise optical structures. This progress has led to the development of the Multilevel Diffractive Lens (MDL), which leverages the ability to pattern multiple discrete phase levels on a flat surface. Unlike the binary phase steps of the FZP, the MDL can manipulate light with higher efficiency and greater design flexibility [3][5]. Additionally, the MDL’s more compact design allows for more efficient use of space, which is beneficial in applications requiring miniaturized optical components.

The potential for cost-effective, high-volume production of MDLs using imprint lithography further enhances their appeal. This manufacturing technique allows for the replication of intricate optical patterns, making MDLs a viable option for commercial applications. Despite these advantages, the complexity of MDL fabrication presents significant challenges. Discrepancies between the designed and fabricated geometries, particularly errors in ring width and height, can adversely affect the lens’s performance [4]. These fabrication constraints have sparked a debate within the photonics community as to whether the performance benefits of MDLs justify replacing the simpler and easier-to-manufacture FZPs.

This study aims to address this debate by comparing the performance of MDLs and FZPs designed with equal geometric parameters and fabrication constraints. By focusing on high numerical apertures (NAs) of 0.7, 0.9, and 0.99, the research seeks to demonstrate that, despite fabrication challenges, MDLsoffer superior efficiency and focusing capabilities. The optimization of MDLs using the direct binary search inverse design algorithm, starting from the FZP design, aims to highlight the potential performance gains achievable with advanced design techniques [5].

Ultimately, this research endeavors to prove that MDLs can outperform FZPs in key performance metrics, such as efficiency, intensity, and depth of field. By validating these findings through simulations conducted with the softwares MEEP and RSoft, the study aims to support the broader adoption of MDLs in advanced optical systems. The successful demonstration of MDLs superior performance could lead to significant advancements in imaging systems, miniaturized optical devices, laser beam shaping, and fiber optics, paving the way for future innovations in these fields.

Methods

To conduct this study, the first step is to design three Fresnel Zone Plates (FZPs) and three Multilevel Diffractive Lenses (MDLs) with identical geometrical parameters and fabrication constraints. These designs will be created for numerical apertures (NA) of 0.7, 0.9, and 0.99. The optimization of each MDLwill be carried out using the direct binary search inverse design algorithm [5], with the initial design guess based on the corresponding FZP. To accurately reflect fabrication constraints, the minimum ring width for both the FZP and MDL will be set to 0.268 μm.

Each design will be simulated at a wavelength of 0.532 μm, utilizing the simulation software MEEP and then with RSoft to validate the results.These simulation softwares use the finite difference time domain (FDTD) computational technique for simulating electromagnetism [6]. Following the simulation, the efficiency of each FZP will be analyzed and compared directly with the efficiency of the corresponding MDL of equal numerical aperture and geometry. This comparative analysis aims todemonstrate the performance advantages of MDLs over FZPs under the same design constraints. This project specifically analyzes the MDL and FZP of NA=0.99.

Results

The Multilevel Diffractive Lens (MDL) demonstrated superior performance compared to the Fresnel Zone Plate (FZP) across various metrics. For each numerical aperture (NA) evaluated, the MDL exhibited higher efficiency, greater intensity, and a shorter depth of field (DOF).

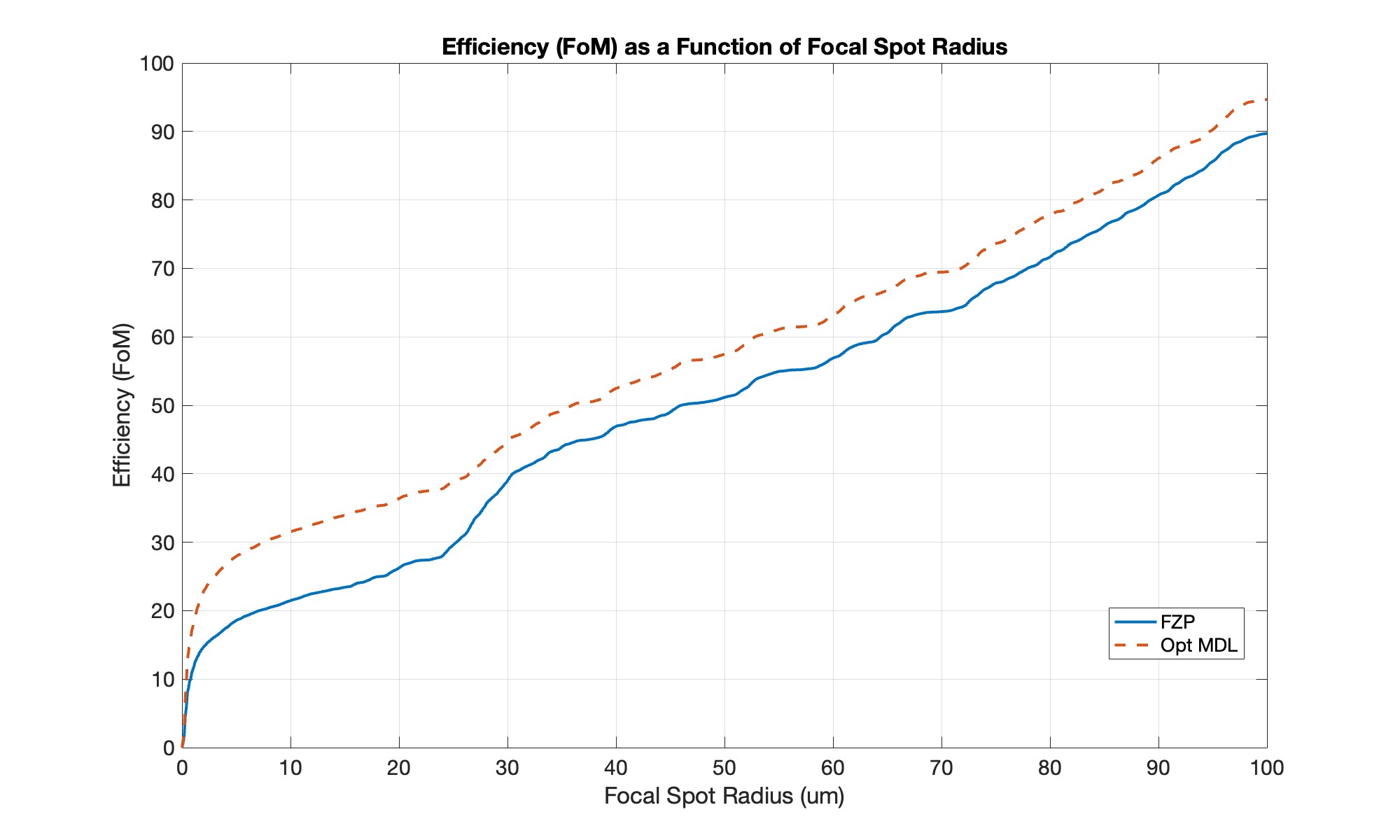

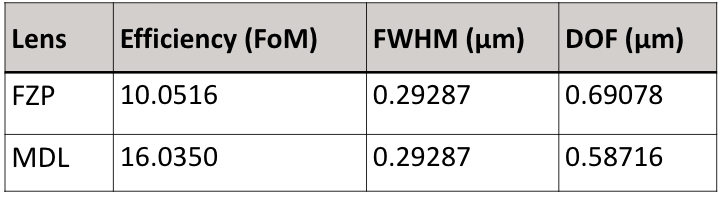

At an NA of 0.99, the MDL achieved an efficiency, measured as the Figure of Merit (FoM), of 16.0350, whereas the FZP only reached an efficiency of 10.0516. This substantial difference highlights the MDL’s superior capability in focusing and transmitting light effectively. Specifically, the MDL’s efficiency was 59.52% greater than that of the FZP.

Figure 2. Encircled Energy of FZP vs. MDL

Figure 2 illustrates the encircled energy comparison between the FZP and MDL, emphasizing the enhanced performance of the MDL. Both lenses demonstrated an equal full-width at half maximum (FWHM)of 0.29287 μm, indicating that they possess identical resolving power and can focus light to the same degree of sharpness. However, the DOF of the MDL was shorter at 0.58716 μm compared to the FZP’s DOF of 0.69078 μm, reflecting a 17.65% reduction. This shorter DOF suggests that the MDL can focus light more tightly, which is beneficial in applications requiring high precision.

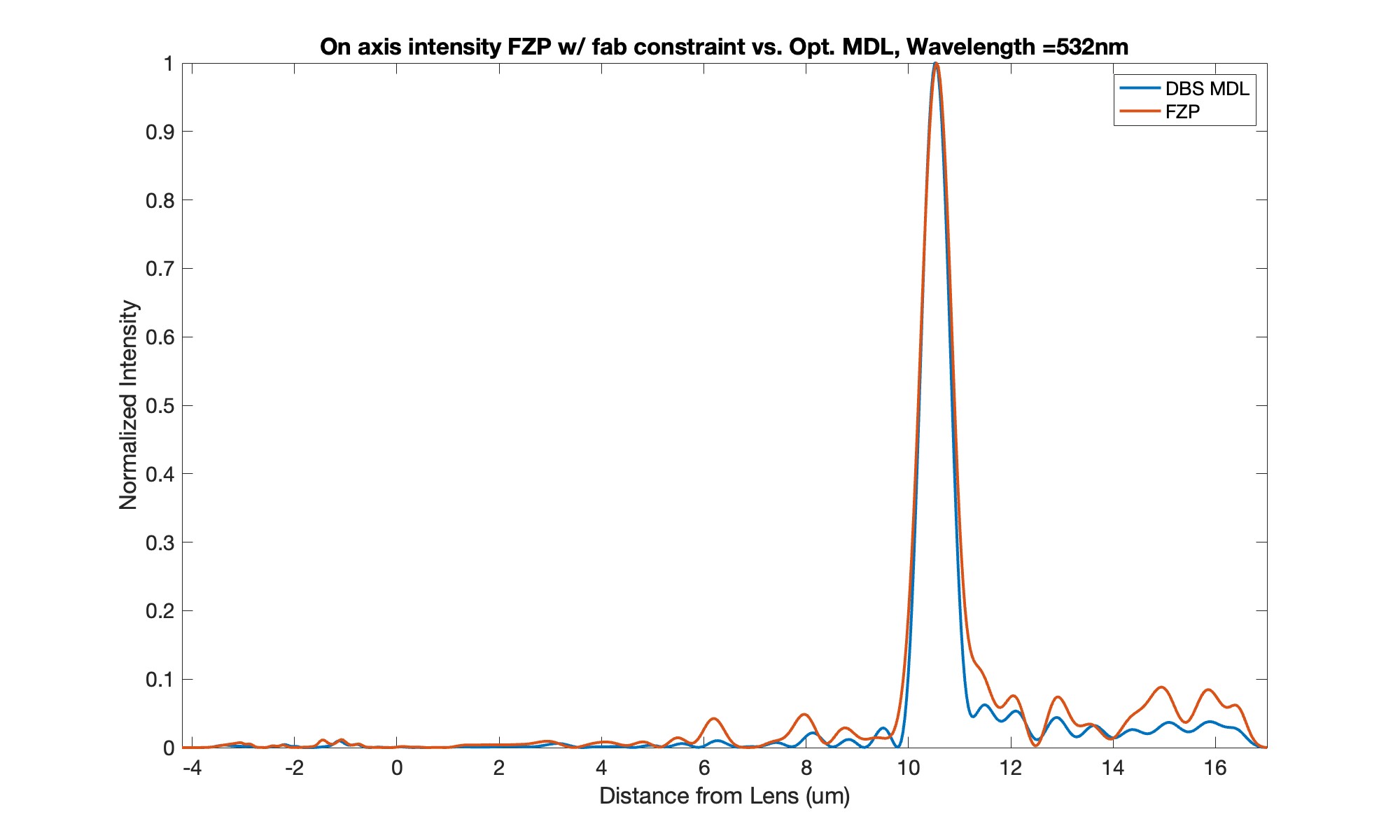

Figure 3. On Axis Intensity of Focal Point, FZP vs. MDL

Moreover, both lenses produced a focal spot slightly beyond 10 μm. Despite this, the intensity distribution of the MDL was better centered, resulting in a more concentrated and efficient focal spot. This characteristic further underscores the MDL’s advantage in applications where focused light intensity and precision are critical.

In summary, the results clearly demonstrate the MDL’s superiority over the FZP in terms of efficiency, intensity, and depth of field, particularly at high numerical apertures. These findings validate the potential of MDLs to replace FZPs in advanced optical systems, providing improved performance despite the more challenging fabrication requirements.

Conclusions

This study set out to evaluate and compare the performance of Multilevel Diffractive Lenses (MDLs) and Fresnel Zone Plates (FZPs) under identical geometric and fabrication constraints, specifically focusing on high numerical apertures (NAs) of 0.7, 0.9, and 0.99. By optimizing the MDLs using the direct binary search inverse design algorithm and validating the designs through simulations with MEEP and RSoft, this research aimed to establish whether MDLs could outperform FZPs despite the inherent fabrication challenges.

The results unequivocally demonstrate the superior performance of MDLs over FZPs across several key metrics. At an NA of 0.99, the MDL achieved a Figure of Merit (FoM) of 16.0350, significantly surpassing the FZP’s FoM of 10.0516. This 59.52% improvement in efficiency underscores the potential of MDLs to achieve higher light transmission and focusing efficiency. Both lenses exhibited identical Full-Width at Half Maximum (FWHM) values of 0.29287 μm, indicating comparable resolving power. However, the MDL’s depth of field (DOF) was 0.58716 μm, 17.65% shorter than the FZP’s DOF of 0.69078 μm, suggesting that the MDL can achieve a tighter and more precise focus.

The MDL’s superior intensity distribution, as indicated by the more centered focal spot, further highlights its advantages in applications requiring precise light manipulation. The encircled energy comparison provided visual evidence of the MDL’s enhanced energy concentration at the focal point, reinforcing its potential for higher efficiency in practical applications.

These findings have significant implications for the future of optical system design. The demonstrated advantages of MDLs in terms of efficiency, intensity, and depth of field make them a promising alternative to FZPs, particularly in advanced optical applications where performance and precision are paramount. Despite the more challenging fabrication process, the benefits of MDLs justify their integration into systems requiring high numerical apertures and precise light control.

Moreover, the potential for cost-effective, high-volume production of MDLs using imprint lithography opens up opportunities for their widespread adoption in commercial and industrial applications. The ability to replicate intricate optical patterns at a lower cost addresses one of the primary barriers to the broader use of MDLs, making them a viable option for various applications, including imaging systems, miniaturized optical devices, laser beam shaping, and fiber optics.

Future research should focus on further refining the fabrication techniques for MDLs to minimize discrepancies between the designed and fabricated geometries. Advances in microfabrication technologies will be crucial in achieving this goal, ensuring that the high diffractive efficiencies observed in simulations can be consistently replicated in practical implementations. Additionally, exploring the integration of MDLs into complex optical systems and evaluating their performance in real-world scenarios will provide valuable insights into their practical advantages and limitations.

In conclusion, this study has demonstrated that, despite fabrication constraints, MDLs offer superior performance compared to FZPs in terms of efficiency, intensity distribution, and depth of field. The findings validate the potential of MDLs to replace FZPs in various optical applications, paving the way for innovations and improvements in imaging, miniaturized optics, and beyond. As fabrication techniques continue to advance, the adoption of MDLs is likely to increase, driving further progress in the field of optical engineering.

Footnotes

[1] Swanson, G.J. (1989) Binary Optics Technology: The Theory and Design of Multi-level Diffractive Optical Elements. DTIC. 53. ADA213404

[2] Hazra, Lakshminarayan. (1999). Diffractive optical elements: past, present, and future. Proc SPIE. 3729. 10.1117/12.346782.

[3] Hayward, Tina & Qadri, Syed & Brimhall, Nicole & Santiago, Freddie & Christophersen, Marc & Dunay, Christopher & Espinola, Richard & Martin, Hector & Cheung, C. & Menon, Rajesh. (2023). Multilevel diffractive lens in the MWIR with extended depth-of-focus and wide field-of-view. Optics Express. 31. 15384. 10.1364/OE.486756.

[4] Banerji, S., Cooke, J. & Sensale-Rodriguez, B. Impact of fabrication errors and refractive index on multilevel diffractive lens performance. Sci Rep 10, 14608 (2020). https://doi.org/10.1038/s41598-020-71480-2

[5] Monjurul Meem, Sourangsu Banerji, Christian Pies, Timo Oberbiermann, Apratim Majumder, Berardi Sensale-Rodriguez, and Rajesh Menon, “Large-area, high-numerical-aperture multi-level diffractive lens via inverse design,” Optica 7, 252-253 (2020)

[6] Oskooi, A. F., Roundy, D., Ibanescu, M., Bermel, P., Joannopoulos, J. D., & Johnson, S. G. (2010). “Meep: A flexible free-software package for electromagnetic simulations by the FDTD method.” Computer Physics Communications, 181(3), 687-702.

Media Attributions

- 137489262_mdl_fzp

- 146879582_optmdl_fzp

- 146879585_on_axis_intensity_w_fab_constraint_fzp_optmdl

- 146881378_table1