1 Value and Flow

Building Blocks of Operational Excellence: Value and Flow

“There are four purposes of improvement: easier, better, faster, and cheaper. These four goals appear in the order of priority.”

The journey to operational excellence begins with understanding two fundamental principles that underpin all successful operations: value and flow. These concepts, originating from lean philosophy, provide the foundation for how organizations should think about and improve their operations.

Value represents the essential purpose of any organization – creating something customers want and are willing to pay for. It answers the fundamental question: “What are we trying to achieve?” Without a clear understanding of value from the customer’s perspective, organizations risk optimizing the wrong things or solving the wrong problems. Value must be defined precisely in terms of specific products or services, with specific capabilities, offered at specific prices to specific customers.

Flow represents how well an organization delivers that value through its processes. It answers the question: “How effectively are we delivering value?” Flow examines how materials, information, and decisions move through an organization’s processes to create value. Perfectflow would mean delivering exactly what customers want, exactly when they want it, with no waste or delay in the process.

These two principles are inseparable in achieving operational excellence:

- Value without flow leads to good intentions but poor delivery

- Flow without value leads to the efficient delivery of the wrong things

- Together, they create the capability to consistently deliver what customers want, when they want it, at a price that works for both customer and provider

Throughout this course, we will repeatedly return to these foundational principles as we explore various tools, techniques, and approaches to operational excellence. Whether examining process design, quality systems, or improvement methodologies, we will always ask two key questions:

- How does this help us better understand or deliver customer value?

- How does this improve the flow of value through our processes?

By maintaining this dual focus on value and flow, organizations can avoid the common trap of implementing improvement tools without a clear purpose and instead build truly excellent operations that consistently deliver superior results.

“It is not the employer who pays the wages. He only handles the money. It is the product that pays the wages.”

Value Creation: The Core Purpose

Organizations exist to create value-transforming inputs into outputs that customers want and are willing to pay for. This transformation process, whether manufacturing products or delivering services, must efficiently combine resources, capabilities, and knowledge to generate outcomes that exceed their input costs. However, value creation goes beyond simple economic calculations. True value encompasses everything from product functionality to customer experience to societal impact.

Understanding Customer Value

Value must be defined through the customer’s perspective, not internal metrics or assumptions. What organizations think is valuable may differ significantly from what customers actually value. This understanding requires:

Deep Customer Insight

Organizations must develop systematic ways to understand customer needs, preferences, and pain points. This goes beyond traditional market research to include direct observation, continuous feedback loops, and deep analysis of customer behavior patterns.

Value Attributes

Customer value has multiple dimensions, including quality, speed, flexibility, and cost. Different customers prioritize these attributes differently. Some may prioritize speed over cost, while others prefer customization over standardization. Excellence requires understanding these trade-offs and designing operations to deliver the right mix of attributes to target customers.

Creating Flow in Processes

Flow represents the smooth, efficient movement of materials, information, and decisions through value-creating processes. Achieving excellence in flow requires:

Removing Barriers

Organizations must identify and eliminate obstacles that interrupt flow. These barriers include physical constraints, information gaps, decision bottlenecks, and organizational boundaries.

Synchronizing Activities

Activities within and across processes must be coordinated to maintain a consistent flow. This includes matching capacity to demand, balancing workloads, and ensuring smooth handoffs between process steps.

Enabling Flexibility

Flow systems must be able to adapt to changing conditions while maintaining efficiency. This requires building appropriate buffers, developing flexible capabilities, and creating robust yet adaptable processes.

Process-Based View of Value and Flow Creation

Value creation happens through processes–interconnected activities that transform inputs into outputs. Understanding and managing these processes effectively is crucial for operational excellence.

Organizations must map and understand their key value-creating processes. This includes core processes that directly create customer value, support processes that enable core processes, and management processes that coordinate and improve the system

3 types of processes

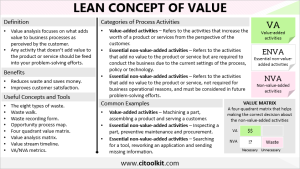

1. Core Processes: Processes that directly add value to a product or service.These are the process steps that change the form, fit, or function of a product.

Examples include manufacturing operations that transform raw materials, software development that creates new features, or service interactions that directly help customers. These processes should be the primary focus of improvement efforts as they directly create customer value.

2. Support Processes: Processes that support core processes and allow them to function, but don’t directly add value to the end product or service the organization aims to create.

Examples include maintenance, IT systems, HR functions, and procurement. While these processes don’t directly create customer value, they are essential for enabling core processes to function effectively

3. Management Processes: Processes that coordinate, support, and aim to improve core processes. Management only adds value if what they do helps score processes function better.

This includes strategic planning, performance management, resource allocation, and improvement initiatives. Effective management processes enable both core and support processes to operate more efficiently and adapt to changing conditions.

+ one: Waste Processes: Process steps that interrupt flow and don’t directly add value, which could potentially be eliminated. Identifying and eliminating waste processes is key to improving flow and operational excellence. Unlike support processes, which are necessary despite not directly adding value, waste processes represent opportunities for elimination or reduction to improve overall flow efficiency.

Understanding these process types helps organizations prioritize improvement efforts, allocate resources effectively, and maintain focus on value-creating activities while ensuring necessary support functions receive appropriate attention. This classification also helps identify opportunities for waste elimination and process optimization across the organization.

Process Integration

Value creation processes don’t exist in isolation. They form complex networks where outputs from one process become inputs for another. Excellence requires understanding and managing these interconnections to ensure smooth flow and prevent local optimizations that harm overall performance.

For example, in an automobile manufacturing plant, the paint shop’s schedule must integrate with both upstream body assembly and downstream final assembly. Optimizing the paint shop’s efficiency in isolation (by running large batches of the same color) might create inefficiencies in final assembly where mixed-model production is needed to meet customer demands.

Process Measurement

Organizations need clear metrics to assess process performance in terms of value creation. These metrics must align with customer value definitions and provide actionable insights for improvement.

For instance, a customer service department might track:

-

- First-call resolution rate (effectiveness)

- Average handle time (efficiency)

- Customer satisfaction scores (value delivery)

- Employee satisfaction (process health)

- Cost per interaction (resource utilization)

The Imperative of Integration

These building blocks of operational excellence – value creation and flow – must work together as an integrated system. Organizations often fail when they focus on one element while neglecting others. Excellence emerges from the thoughtful integration of all these elements, creating a coherent system that consistently delivers superior value to customers.

Discussion Questions:

- How does your organization define and measure customer value?

- What are the major barriers to flow in your key processes?

- How well integrated are the different elements of value creation in your organization?

Self-Assessment Questions:

- What are the key dimensions of customer value?

- How does the process architecture and integration affect value creation?

- What are the main requirements for creating flow in processes?

Media Attributions

- ValueAnalysisP