2 Frameworks and Introduction to TIM WOODS

The Path to Excellence: Using Frameworks

The journey toward operational excellence can seem overwhelming. Organizations face complex challenges across multiple dimensions- from process design to people management, from technology implementation to cultural transformation. To navigate this complexity, leaders need structured approaches that help them see the whole picture while maintaining focus on specific improvement opportunities.

Frameworks provide this crucial structure. They serve as mental models that help organizations:

- Organize knowledge and insights

- Guide decision-making

- Focus improvement efforts

- Measure progress

- Build a common understanding

The TIM WOODS Framework

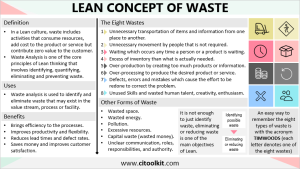

In this course, we will use the TIM WOODS framework powerful lens for identifying and eliminating waste in operations. This framework, derived from lean principles, identifies eight fundamental types of waste that impede value creation and flow:

- Transportation: Unnecessary movement of materials, products, or information.

- Inventory: Excess materials, work-in-process, or finished goods

- Motion: Unnecessary movement of people

- Waiting: Delays between process steps

- Overproduction: Making more than needed or before needed

- Over-processing: Doing more work than necessary to meet customer needs

- Defects: Errors requiring rework or causing scrap

- Skills: Under-utilization of people’s capabilities

Each waste type represents opportunities for improvement that directly impact both value creation and flow. By systematically addressing these wastes, organizations can build excellence into their operations.

Weekly Deep Dives

Each week, we will explore one type of waste in detail:

Week 1: Transportation

- Impact on value creation and flow

- Common causes and symptoms

- Assessment tools and metrics

- Improvement strategies and best practices

Week 2: Inventory

- Understanding inventory’s role in operations

- Distinguishing necessary from wasteful inventory

- Impact on cash flow and organizational agility

- Techniques for inventory optimization

Week 3: Motion

- Analyzing workplace layout and design

- Ergonomics and worker safety

- Standard work development

- Workplace organization methods (5S)

Week 4: Waiting

- Process timing and synchronization

- Queue management

- Critical path analysis

- Load leveling and flow balancing

Week 5: Overproduction

- Pull systems versus push systems

- Demand-driven operations

- Batch size optimization

- Production scheduling strategies

Week 6: Over-processing

- Value analysis

- Process simplification

- Customer requirements alignment

- Quality at the source

Week 7: Defects

- Quality management systems

- Root cause analysis

- Error-proofing (Poka-Yoke)

- Cost of quality

Week 8: Skills

- People development systems

- Knowledge management

- Cross-training strategies

- Employee engagement

Building Excellence Through Framework Application

Each week builds upon previous learning, creating a comprehensive understanding of operational excellence. As we explore each waste type, we will:

Connect to Value Creation

- How does this waste type affect customer value?

- What is the cost impact of this waste?

- How does eliminating this waste improve competitive advantage?

Analyze Flow Impact

- How does this waste interrupt flow?

- What are the ripple effects through the system?

- How do improvements in this area enhance overall flow?

Develop Practical Solutions

- What tools and techniques address this waste?

- How can improvements be sustained?

- What metrics indicate success?

Consider Integration

- How does this waste interact with others?

- What are the trade-offs in improvement efforts?

- How do solutions affect the entire system?

The Power of Systematic Improvement

By using the TIM WOODS framework, organizations can:

- Break down the complexity of operational excellence into manageable components

- Create a common language for improvement

- Prioritize improvement opportunities

- Measure progress systematically

- Build sustainable excellence

Throughout the course, we will use real-world examples, case studies, and hands-on exercises to bring these concepts to life. Students will learn not just the theory behind each waste type, but practical methods for identifying, measuring, and eliminating these wastes in their own organizations.

Remember: Excellence is not achieved through isolated improvements but through the systematic elimination of waste across all dimensions of operations. The TIM WOODS framework provides the structure for this journey, helping organizations move steadily toward their goal of operational excellence.

Discussion Questions:

- How does your organization currently identify and address operational waste? What frameworks, if any, are you using?

- Which of the eight wastes do you think is most prevalent in your organization, and why?

- How might focusing on waste reduction through the TIM WOODS framework help your organization better deliver customer value and improve flow?

Self-Assessment Questions:

- What are the eight types of waste identified in the TIM WOODS framework?

- How does a framework differ from a simple tool or technique in driving operational excellence?

- Explain how the systematic elimination of one type of waste might impact other types of waste in an operation.

Media Attributions

- WasteAnalysisP

- WasteAnalysisG