5 Walter Shewhart

Quality processes lead to quality products, Statistical Process Control, in-control processes, common cause and special cause variation

Jonathan Ebbeler; Rick Hardcopf; and Mike Dixon

Walter Shewhart (1891 – 1967)

The year 1931 marked many milestones, including Thomas Edison’s application for his last patent, the adoption of the Star-Spangled Banner as the national anthem of the United States, and the completion of the world’s tallest building, the Empire State Building. This was also the year that Walter Shewhart’s pivotal tome, Economic Control of Quality of Manufactured Product, was published. This publication was the first foray into the use of mathematical statistics to deal with industrial management. Shewhart understood that management processes could be created and adopted to help drive quality and profitability by utilizing Statistical Process Control (SPC). This new line of thinking and toolset launched most of the frameworks and movements that address quality today.

Walter Andrew Shewhart was born in 1891 in New Canton, Illinois. He received his bachelor’s and master’s degrees in physics and earned his Ph.D. in 1917 at the University of California, Berkeley. In 1918, Shewhart was hired by the Western Electric Company in Illinois. The company was a hardware manufacturer for the Bell Telephone Company and a fertile breeding ground for leaders in the quality movement.

When Shewhart joined the Western Electric Company, product quality control was limited to identifying and removing defective products after inspection of the finished good. Its customer, Bell Telephone, focused on engineering better solutions to address the reliability of telephone transmission systems and components buried underground. Shewhart worked on improving the clarity of transmissions in telephone handsets, applying principles of statistical variation in the central telephone switching station, and, lastly, to the factory production process.

A couple of crucial findings from this work would later lead to the development of Statistical Process Control (SPC). First, variation during the manufacturing and production process leads to increased costs; he showed that it is critical that companies focus their improvement efforts on reducing a system’s variation. Second, constantly adjusting and re-adjusting steps in a process to address variation and non-conformance led to even more significant variation and quality degradation; some level of variation in a process was to be expected and managers should not react to all differences. Using statistical principles of sampling and the central limit theorem, Shewhart hypothesized that manufacturing processes could be measured over time and plotted on a line chart. After a number of observations were measured, a mean and standard deviation could be estimated for the processes and managers could better understand if a variation had a special cause.

Shewhart’s supervisor at Western Electric was George D. Edwards, the first president of the American Society for Quality. In 1924 Shewhart’s articulated his revolutionary ideas about manufacturing quality and process control in a simple memo to Edwards who later recounted that, “Dr. Shewhart prepared a little memorandum only about a page in length. About a third of that page was given over to a simple diagram which we would all recognize today as a schematic control chart. That diagram, and the short text which preceded and followed it, set forth all the essential principles and considerations which are involved in what we know today as process quality control.”[2] This led Shewhart to draft and create the first statistical control process charts of manufacturing processes that employed statistical sampling procedures. The findings were the nexus of his seminal book, Economic Control of Quality of Manufactured Product.

The new approach to manufacturing process control was limited in its impact beyond Wester Electric until Shewhart was invited by a former summer intern, W. Edwards Deming, now of the US Department of Agriculture, to give a series of talks in 1938. These talks were edited by Deming and resulted in Shewhart’s second book, Statistical Method from the Viewpoint of Quality Control, which applied statistical methods to operational questions within manufacturing processes. In the book, Shewhart espoused fundamental principles of statistical techniques, including establishing tolerance limits and specifying precision. The book outlined quality improvement techniques, including establishing process control, implementing control charts to identify types of variation, and using a Specification-Production-Inspection cycle of continuous improvement (Shewhart Cycle).

During World War II, Shewhart consulted with the US War Department, the United Nations, and the government of India. On his suggestion, the Office of Production and Research and Development created a nationwide program to provide Federal assistance to American war industries to implement statistical quality control.[3] He continued his career lecturing extensively on the topics of applied statistics and quality control at the Indian Statistical Institute at Calcutta, the University of London, the Stevens Institute of Technology, and at the Department of Agriculture. Following the war (in 1948), the American Society for Quality Control (later named the American Society for Quality) created the prominent Shewhart Medal to recognize and award advances in “outstanding technical leadership in the field of modern quality control, especially through the development of its theory, principles, and techniques.”[4] The award continues to this day.

Statistical Process Control

The underlying principle of SPC is that the quality of a product can be ensured if the process used to make the product is controlled, that is, if a process used to make a product is high quality, the product will be high quality. SPC aims to measure the consistency of a process and attempts to identify variances.

Dr. Shewhart’s first book, Economic Control of Quality of Manufactured Product, introduced the concepts of chance-cause (common cause) and assignable-cause (special cause) variation in a production process. Common cause variation is typical and customary. It is the ” noise ” inherent in all processes which can only be eliminated by redesigning the process. In contrast, special cause variation is atypical and unexpected. In theory, it has an assignable cause which can be discovered through investigation and resolved.

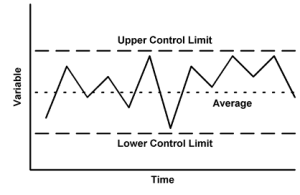

Dr. Shewhart created a control chart to differentiate between the two types of variation. In ‘control charting’, process samples are gathered regularly and measurements from the samples are graphed on a control chart (see picture above). Various rules are used to identify special cause variation, such as when a datapoint falls outside the mathematically derived control limits. By regularly gathering samples, mapping sample performance on the control chart, and removing sources of special cause variation (when possible), Shewhart concluded that process variation can be reduced and process quality improved.

The Big Idea for Operations Management

Dr. Shewhart is known as the father of statistical quality control. His method for implementing statistical process control has changed little over the years and continues to be used extensively to control processes of all types, in all settings, around the globe. His ideas around manufacturing quality and process control influenced other seminal OM thinkers. For example, his ideas regarding statistical process control and common and special cause variation influenced the development of Six Sigma and quality management. His ideas continue to resonate with operations management professionals and scholars yet today.

Sources

[1] J. L. Smith, “Remembering Walter A. Shewhart’s Contribution to the Quality World,” Qual. Mag., 2009.

[2] Western Electric, “Western Electric – A Brief History,” Western Electric History, 2023. https://www.bellsystemmemorial.com/westernelectric_history.html#Western Electric – A Brief History

[3] J. Lawson, An Introduction to Acceptance Sampling and SPC with R. Chapman and Hall/CRC, 2021.

[4] ASQ, “Shewhart Medal,” ASQ, 2023. https://asq.org/about-asq/asq-awards/shewhart

Image source (Control Chart): https://www.pngegg.com/en/png-pbbhq/download